Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=100087112105480

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

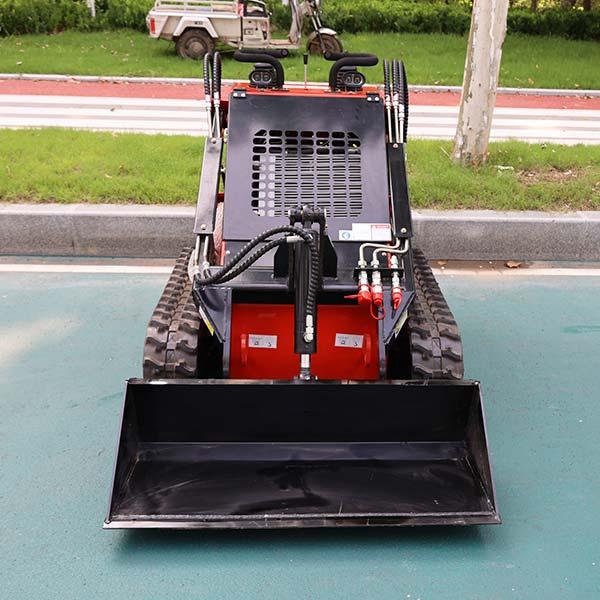

If you’re managing construction, landscaping, agriculture, or earthmoving projects, choosing a crawler skid steer loader can be a game‑changer. It delivers tracked traction and skid‑steer maneuverability in tough environments. You’ll learn how this loader excels in low ground pressure, slope stability, and tight‑space agility, helping you minimize downtime and boost efficiency on site.

What Defines a Crawler Skid Steer Loader

Core Features and Track Mobility

A crawler skid steer loader features continuous tracks instead of wheels, paired with hydraulic skid‑steer steering. Its low ground pressure keeps it from bogging down in mud or soft soil, while zero‑radius turning lets it navigate tight spaces with ease.

How It Differs from Wheeled Variants

While wheeled loaders work well on paved or firm surfaces, they struggle in loose or uneven terrain. The tracked alternative provides consistent traction and stability—even on slopes or gravel—making it ideal for varied site conditions.

Performance Advantages of Crawler Skid Steer Loader

Low Ground Pressure for Sensitive Terrain

Tracks distribute weight evenly, exerting much lower pressure on ground—often 2 psi versus 5 psi with wheels. That significantly reduces surface damage and risk of rutting in delicate areas.

Enhanced Stability and Slope Capability

Equipped to safely climb slopes of up to 30°, crawler skid steer loaders maintain balance where wheeled machines may slip, making them indispensable for hillside jobs.

Site Maneuverability in Tight Spaces

The skid‑steer mechanism enables a zero‑turn radius—ideal for confined job sites, basements, or urban areas where space is limited.

Tough Build & Mechanical Design

Durable Track System

Tracks are built with rugged rubber or steel cores and reinforced joints, preventing debris intrusion. Track width and length correlate to weight class, optimizing flotation.

Reinforced Frame & Protection

Underbody skid plates and rock guards shield driveline components. The lift arms are reinforced for consistent attachment performance even under heavy loads.

Hydraulic and Powertrain Strength

Powered by high‑torque engines and rugged hydraulic pumps, these machines maintain consistent power to attachments like buckets, breakers, or augers—even under demanding cycles.

Common Applications & Use Cases

Site Prep and Earthmoving in Confined Areas

When preparing a construction site surrounded by fencing or structures, tracked loaders move soil efficiently with minimal disturbance to surroundings.

Demolition & Recycling Work

With grapples or mulchers attached, crawler loaders handle debris piles and uneven terrain better than wheeled machines.

Landscaping & Trenching

High breakout force plus traction makes them ideal for stump removal, trenching, and planting in varied soil conditions.

Agriculture and Wetland Work

In paddocks and fields, crawler loaders operate without sinking or damaging sensitive surfaces—perfect for irrigation or drainage tasks.

Comparison: Crawler vs. Wheeled Skid Steer Loader

| Scenario | Wheeled Loader | Crawler Skid Steer Loader |

|---|---|---|

| Mud/Wet/Frozen Ground | Prone to slipping | Excellent flotation |

| Slopes & Uneven Terrain | Limited stability | Stable up to 30° inclines |

| Tight Spaces & Maneuverability | Good | Best with zero‑turn radius |

| Surface Protection | Can damage ground | Low‑impact footprint |

| Attachment Capability | Moderate traction | High under load |

| Maintenance Needs | Tire upkeep | Track and undercarriage care |

Selecting the Right Crawler Skid Steer Loader

Track Type, Width & Ground Pressure

Choose track width based on load class and surface. Wider tracks reduce pressure but impact terrain access.

Engine, Flow Rate & Power

Pick a high‑torque powertrain with sufficient low‑rpm torque. Match hydraulic flow to attachment needs for optimal performance.

Cab, Controls & Ergonomics

Look for enclosed ROPS/FOPS options with joystick or lever control systems. Better ergonomic design means less operator fatigue.

Serviceability & Maintenance

Regular service includes track tension checks, undercarriage cleaning, and hydraulic inspections. Opt for machines with easy‑access panels to reduce downtime.

Jobsite Handling & Transport Efficiency

These loaders are trailer‑friendly, though tracked units take more care to load. On site, they run smoothly without specially prepared paths—cutting setup time and equipment needs.

Conclusion

A crawler skid steer loader delivers unmatched traction, stability, and maneuverability in the toughest conditions. Whether you work in mud, slopes, limited space, or need strong attachment performance, this machine delivers.

If you’re ready to upgrade site efficiency and reduce equipment downtime, our team is here to help you select the right model, specs, and service options for your needs.

Contact us today to learn how a crawler skid steer loader built for tough jobs can elevate your operation.

FAQ

Are tracked loaders overkill for basic landscaping?

Not if your site has slopes, wet patches, or soft soil—they preserve turf and track better than wheeled units.

Do tracks cost more than tires?

Initial cost and maintenance are higher, but reduced downtime often makes them more cost‑effective long term.

Will attachments fit both tracked and wheeled models?

Yes—if hydraulic flow and mount systems align, attachments work across models.

How often should track tension be checked?

Weekly inspections in tough conditions are recommended; adjust and replace when wear exceeds 50%.

Can these work in snow or winter jobs?

Absolutely. Low ground pressure and traction make them excellent for snow removal and cold‑weather maintenance.