- Phone: +86 15092695795

- E-Mail: sales8@buy-machine.com

Mini Tractor 1004B

Overall Dimension (LWH):4200*1800*2630mm

Min. Operating Weight:2980 kg

Wheelbase:2045 mm

Wheel Track (Front/Rear):1350 / 1350–1600 mm (Steplessly adjustable)

- Efficient global shipping

- High quality product guarantee

- Products can be customized according to your needs

- Comprehensive customer service process

Product Description

As the flagship model, 1004(B) delivers 100 HP powered by a high-pressure common rail engine, achieving an injection pressure of 1800 bar for finer fuel atomization. This design reduces fuel consumption by 8% per 100 km while meeting National IV emission standards.

Its 12F+12R shuttle shift system features a steering wheel side-mounted design, with the forward–reverse lever positioned on the right side of the steering wheel. Combined with a fully flat floor, this layout minimizes driver movement during direction changes and reduces fatigue by up to 30% during continuous operation.

The vehicle adopts a modular body design, with an optional cab equipped with heating, air conditioning, and a suspension seat. Noise insulation is controlled at approximately 60 decibels, significantly enhancing operator comfort.

The hydraulic system utilizes load-sensing technology, automatically adjusting flow according to equipment demand. When operating a 3-meter-wide combined soil preparation machine, energy consumption is reduced by 15% compared to conventional hydraulic systems.

The three-point linkage offers a lifting capacity of up to 1800 kg, supporting agricultural implements up to 5 tons. Optional third and fourth hydraulic outputs enable operation of intelligent equipment such as precision seeders and variable-rate fertilizer applicators, supporting full mechanization of tilling, sowing, and field management.

Key components have been comprehensively upgraded for reliability. The engine block is manufactured from vermicular cast iron, increasing explosion resistance by 40%. The gearbox is equipped with maintenance-free bearings, extending service intervals to 2000 hours. The PTO output shaft comes standard with a safety clutch that automatically disengages in case of equipment jamming, effectively preventing damage.

In addition, the machine is equipped with reserved smart terminal interfaces for integration with agricultural IoT systems, enabling operation tracking, fuel consumption monitoring, and early fault warnings—serving as both a high-intensity powerhouse and an intelligent platform for modern smart agriculture.

Product Parameters

| Category | Item | Specification |

| Dimensions & Weight | Overall Dimension (LWH) | 4200*1800*2630 mm |

| Min. Operating Weight | 2980 kg | |

| Wheelbase | 2045 mm | |

| Wheel Track (Front/Rear) | 1350 / 1350–1600 mm (Steplessly adjustable) | |

| Engine | Model / Brand | Yangdong Stage II |

| Type | Vertical, water-cooling, four-stroke, common rail | |

| Cylinder Count | 4 | |

| Rated Power | 100 HP / 73.5 kW | |

| Rated Speed | 2200 r/min | |

| Drive Train | Clutch | Single disc, dry, independent control, dual stage |

| Gearbox | 12F + 12R | |

| Gear Shift Type | Shift sleeve | |

| Steering & Brake | Steering Type | Full hydraulic steering |

| Brake Type | Mechanical control, wet, disc | |

| Walking Device | Tire Size (Front/Rear) | 9.5-24 / 14.9-30 |

| Working Device | Suspension Type | Rear, three-point suspension, Category II |

| Adjustment Mode | Height adjustment, floating control | |

| Hydraulic Output | 2 groups | |

| Standard PTO Speed | 8 or 6 keys; 760/850 or 540/1000 rpm | |

| Safety & Optional | Protection | ROPS (Roll-over protection structure) |

| Optional Equipment | Luxury AC cabin, heating cabin, swing traction, quick suspension, Sida engine |

Send Us a Message

FAQ

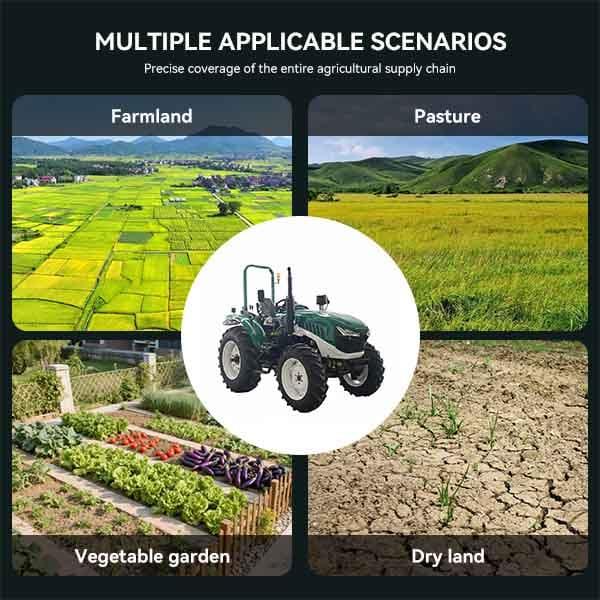

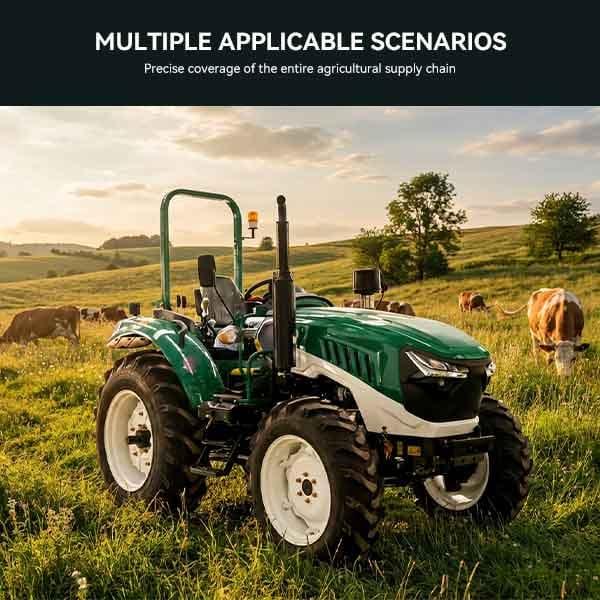

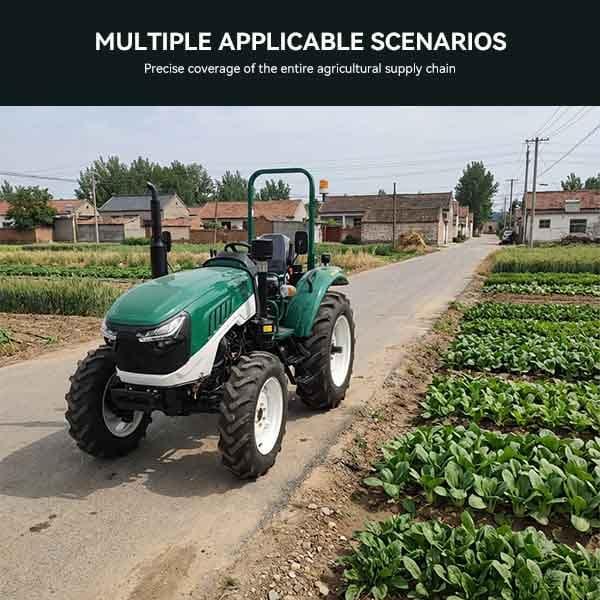

Our products serve a variety of industries, including manufacturing, logistics, agriculture, construction, and landscaping.

We provide a wide range of high-quality machinery, including excavators, tractors, skid steer loaders, and tricycles, tailored to meet diverse operational needs.

Yes, we work closely with clients to understand their specific requirements and can provide customized machinery solutions to suit their unique needs.

We source all products from trusted factories with whom we maintain long-term partnerships, ensuring high-quality standards, competitive pricing, and reliable delivery schedules.

Our products are distributed globally, with a strong focus on markets in Asia, Europe, and North America.